When specifying construction products for a building, the building envelope, and air barriers in particular, may seem like a small consideration among many other critical materials to select. However, air barriers act as a critical line of defense against moisture, vapor, and heat flow, significantly affecting indoor air quality, building maintenance, and energy performance.

Choosing the right air barrier for a commercial building requires navigating a profusion of brands and features, understanding regulations and standards, and factoring in supply and budgets—all while accounting for the priorities of installers. When every product on the market touts varying advantages across metrics such as water holdout, vapor permeability, tear strength, and more, it can be difficult to determine the best fit.

This guide delves into key considerations when selecting an air barrier, helping provide architects and specifiers with the necessary insights to make optimal choices that both meet project requirements and ensure the continued success of the building envelope.

The second most critical function of your building’s wall assembly is managing the heat flow, airflow, and moisture flow into and out of the building. The air barrier does most of this work.

Controlling each of these three flows is crucial to complying with building codes and maintaining the integrity and comfort of the building’s interior. Liquid water that enters the structure can lead to mold, rot, and unhealthy air quality. Excessive air and heat exchange can create energy management and air quality issues.

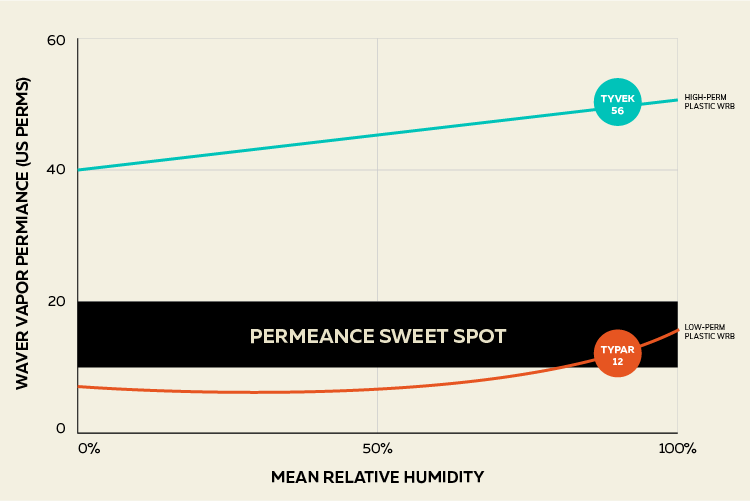

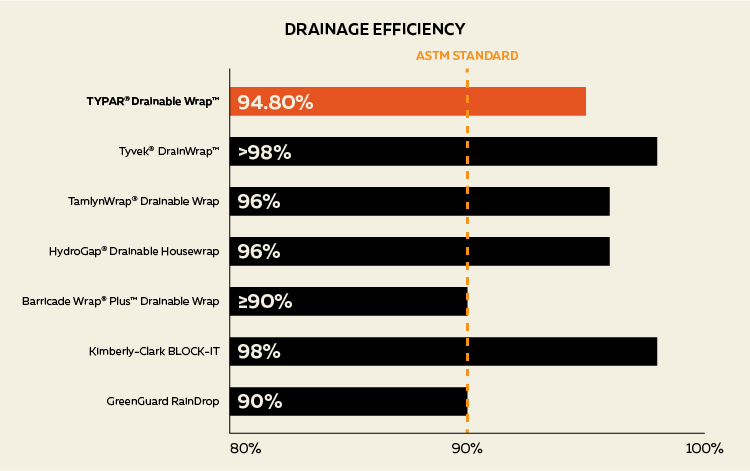

The good news is that the ability of an air barrier to control these factors is easily measured and can be compared across products. The critical metrics to examine are moisture vapor transmission (MVT), which is measured in perms and illustrates how much vapor is allowed through the barrier, and drainage efficiency (how much of the liquid water that gets past the barrier is properly drained away so that it does not cause damage). An MVT value that is too high lets through too much vapor, and a value that is too low lets in too little. Drainage efficiency should be above 90% to pass ASTM standards and effectively prevent water damage.

You know that your specification recommendations aren’t always followed, and one of the reasons is that contractors are often thinking of installation factors and how they can optimize their own processes. By choosing a product that accounts for their needs, you can help ensure specifications are followed more accurately.

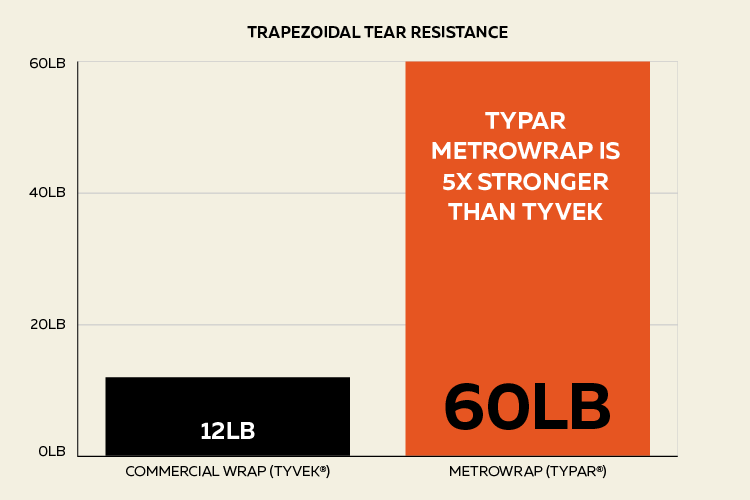

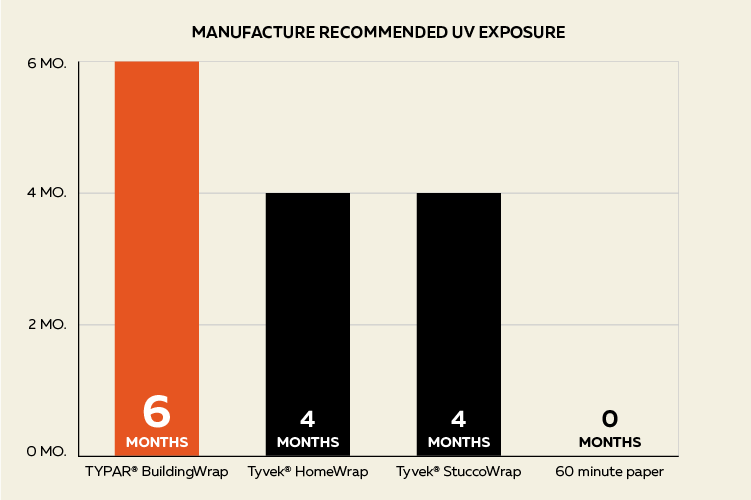

The most critical air barrier installation considerations are tear resistance, which affects ease of application, and ultraviolet (UV) light resistance, which is crucial when variability in construction schedules can cause delays.

An air barrier that tears during application immediately becomes less effective. And while patches can correct errors, they take time and effort and reduce overall confidence in the applied barrier. Tear resistance is tested for against ASTM standards and measured in pounds, and higher tear resistances make application easier, faster, and more cost effective.

Air barriers degrade over time in sunlight. This occurs most often when they are applied to sheathing and left exposed to UV light due to construction delays. Higher UV ratings give construction teams more flexibility and assurance that the barrier won’t fail by the time its covered.

An air barrier doesn’t exist in isolation. It requires an entire system of accessories that come together to connect the air barrier assemblies and seal the structure properly, such as flashing and tapes. Mixing air barrier and accessory brands can cause complications. Construction teams may be unfamiliar using and applying materials from select brands; other times, accessories may be incompatible with your chosen air barrier manufacturer or may not seal as effectively. Material manufacturing and supply must be consistent across your chosen air barrier products.

Long-term performance should be considered in your decision to specify a product. How well will the air barrier you choose serve your project over the years of a building’s lifespan?

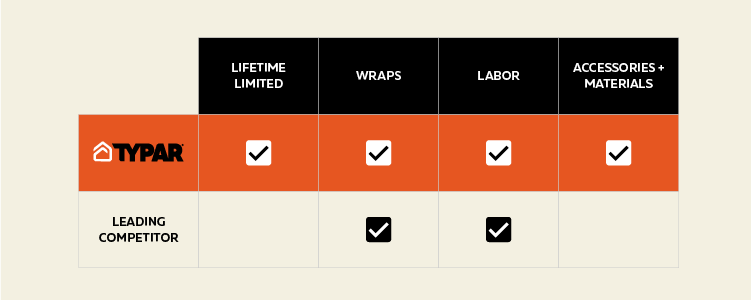

Any product you specify will come with a warranty, but the depth and breadth of warranty terms can vary drastically. Warranty terms can cover various components, including the air barrier’s wrap, labor, and accessories. While coverage of the wrap itself is common, few manufacturers apply that warranty to the entire system. Extensive coverage over a longer period can be a mark of the manufacturer’s confidence in the product’s performance and long-term durability.

That’s a lot of parts to think about for a product that a lot of specifiers and architects don’t think too much about.

Going with the default choice that everyone seems to be using may feel faster and easier—but to really trust that the products you’ve specified are going to do the job well and last the lifetime of the building, it is important to consider the many factors that lead to its success.

The success of your building relies on the specifications, so you need an air barrier you can rely on. For your next commercial building, account for all these factors and consider how your specification can maximize protection, durability, construction efficiency, comfort, and energy usage—all due to a single product. Evaluate the core measures of moisture vapor transmission and drainage efficiency; installation considerations like UV resistance and tear strength; and product-level features like a complete system and warranty.

TYPAR has spent decades engineering an optimal air barrier with one-of-a-kind technology and best-in-class performance. Our wraps provide a better choice, with demonstrated performance, easy installation, and proven durability. We give architects, specifiers, contractors, and tenants ultimate assurance, supported by a 15-year limited warranty that gives you peace of mind and helps your clients build trust in the quality of your services.

Share

We’ve spent decades engineering the optimal air barrier, with one-of-a-kind technology, leading performance and a supportive warranty. Find out how you can specify a better wrap with TYPAR.

Understanding Building Codes and Weather-Resistant Barriers

Five Factors That Affect Indoor Air Quality, and Strategies to Address Them

Building Wrap Performance Compared, by the Numbers